SMC IP8100 Electro-pneumatic positioner for automatic control Valve

Product Characteristics

1. IP8100 E/P positioner is more compact than the IP6000 ,improved visibility of the pressure indicator.

2. improved enclosure protection IP65, interchangeable mounting, excellent shock and vibration performanceThe IP200 cylinder positioner provides accurate and stable positioning of air cylinders.

3. The compact design allows easy installation and maintenance.

4. A span adjuster and zero adjuster are provided for the adjustment of the feed back spring.

5. Output current (4-20mADC) realizes remote position detecting (rotary type)

6. Vibration resistance: No resonances 5 to 200Hz

7. Dust resistance: Conforms to JIS F8007 IP65.A centralized exhaust system employs the combination of the check valve and the labyrinth effect enhancing both dust resistance and water resistance performance.

8. Folk lever joints (Rotary type):Can absorb off-centering.

9. A span adjuster achieves 1/2 split range.

10. Opening current transmission (4 to 20mA DC) Can detect remote position. Non-explosion proof rotary type only.

11. Mounting dimensions are same as convention types, series IP6000/6100.

12. Pressure gauge(O.D.ø43): Enlarged O.D. allows improved visibility.

13. External scale plate (Rotary type): Improved visibility of opening indicator.

14. With terminal box (Explosion proof):No terminal box (non-explosion proof) is available.

Technical Parameters

|

ITEM |

IP8000 |

IP8100 |

||

|

Single action |

Double action |

Single action |

Double action |

|

|

Input Current |

4 to 20m ADC*Note 1 |

|||

|

Input Resistance |

235±15Ω (4 to 20m ADC) |

|||

|

Supply air pressure |

0.14 to 0.7 Mpa |

|||

|

Standard stroke |

10 to 85mm (Deflection angle 10 to 30°) |

60 to 100° *Note 2 |

||

|

Sensitivity |

Within 0.1%F.S. |

Within 0.5% F.S. |

||

|

Linearity |

Within ±0.1%F.S. |

Within ±2.0%F.S. |

||

|

Hysteresis |

Within ±0.75%F.S. |

Within 1% F.S. |

||

|

Repeatability |

Within ±0.5%F.S. |

|||

|

Coefficient temperature |

Within 0.1%F.S. / ℃ |

|||

|

Supply pressure fluctuation |

Within 0.3%F.S. / 0.01Mpa |

|||

|

Output flow |

80l/min (ANR) or more (SUP = 0.14MPa) |

|||

|

200l/min (ANR) or more (SUP = 0.4MPa) |

||||

|

Air consumption |

3LPM (Sup=1.4kgf/cm2, 20psi) |

|||

|

Ambient and fluid temperature |

-20 to 80℃ (Non-explosion proof) |

|||

|

Explosion proof construction |

Flame proof and explosion proof construction: ExdIIBT5 |

|||

|

Air port |

Rc 1/4 female |

|||

|

Electrial connection |

G 1/2 female |

|||

|

Wiring method |

Flame proof packing system, Sealant fitting system (explosion-proof) |

|||

|

Resin G 1/2 connector (Non-Explosion proof, option) |

||||

|

Exterior covering enclosure |

JISF8007, IP65 (conforms to IEC Pub.529) |

|||

|

Material |

Aluminum diecast body / epoxy resin |

|||

|

Weight |

With terminal box 2.6kg (None 2.4kg) |

|||

| Note 1: 1/2 Sprit range (Standard) Note 2: Stroke adjustment: 0 to 60°C, 0 to 100℃ |

||||

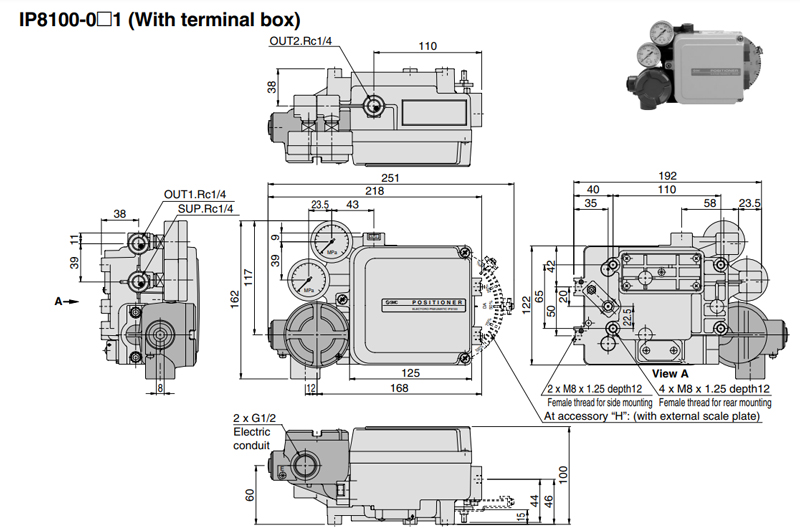

Product Size

Certifications

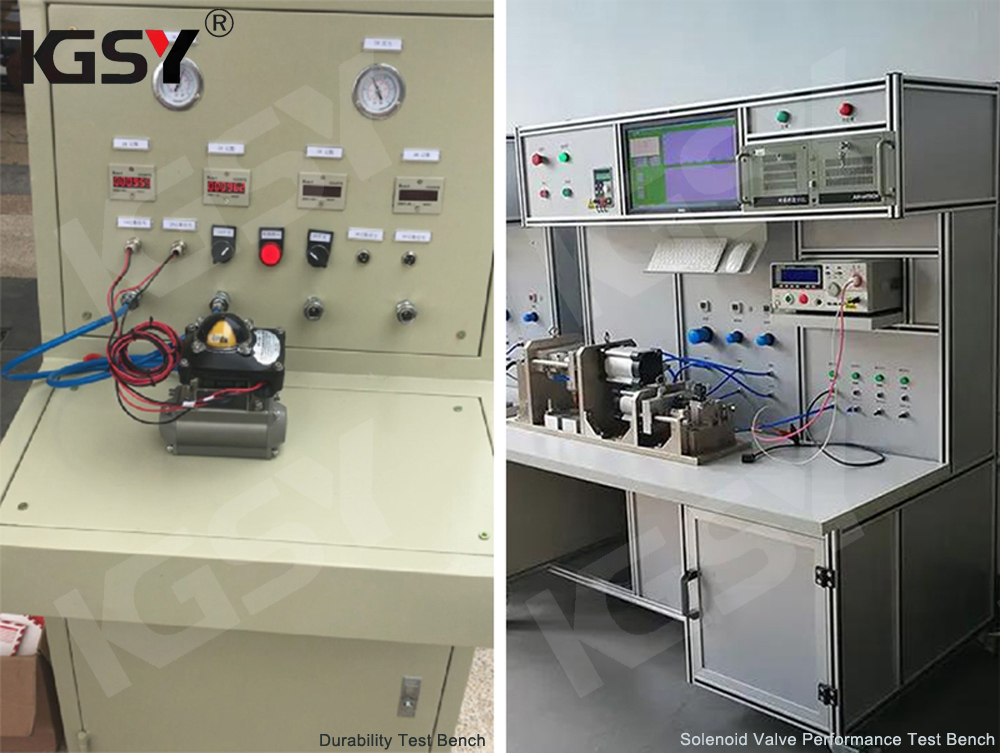

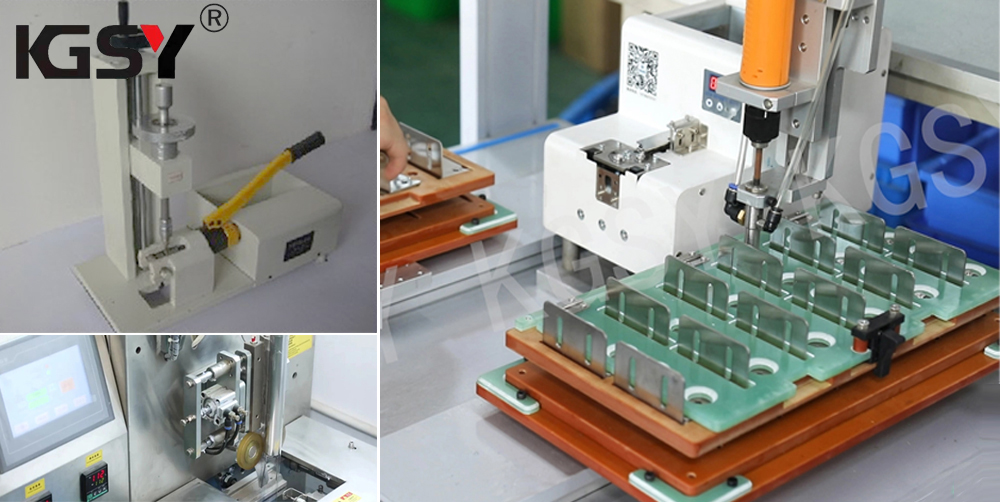

Our Factory Appearance

Our Workshop

Our Quality Control Equipment